Eco Shredder 500

Intro →

Ecooffset has achieved another milestone with an ultimate solution for sustainable packaging and shipping needs in Ireland.

Now introducing, Eco-Shredder 500, in collaboration with MIKEA® to make reusable material efficiently.

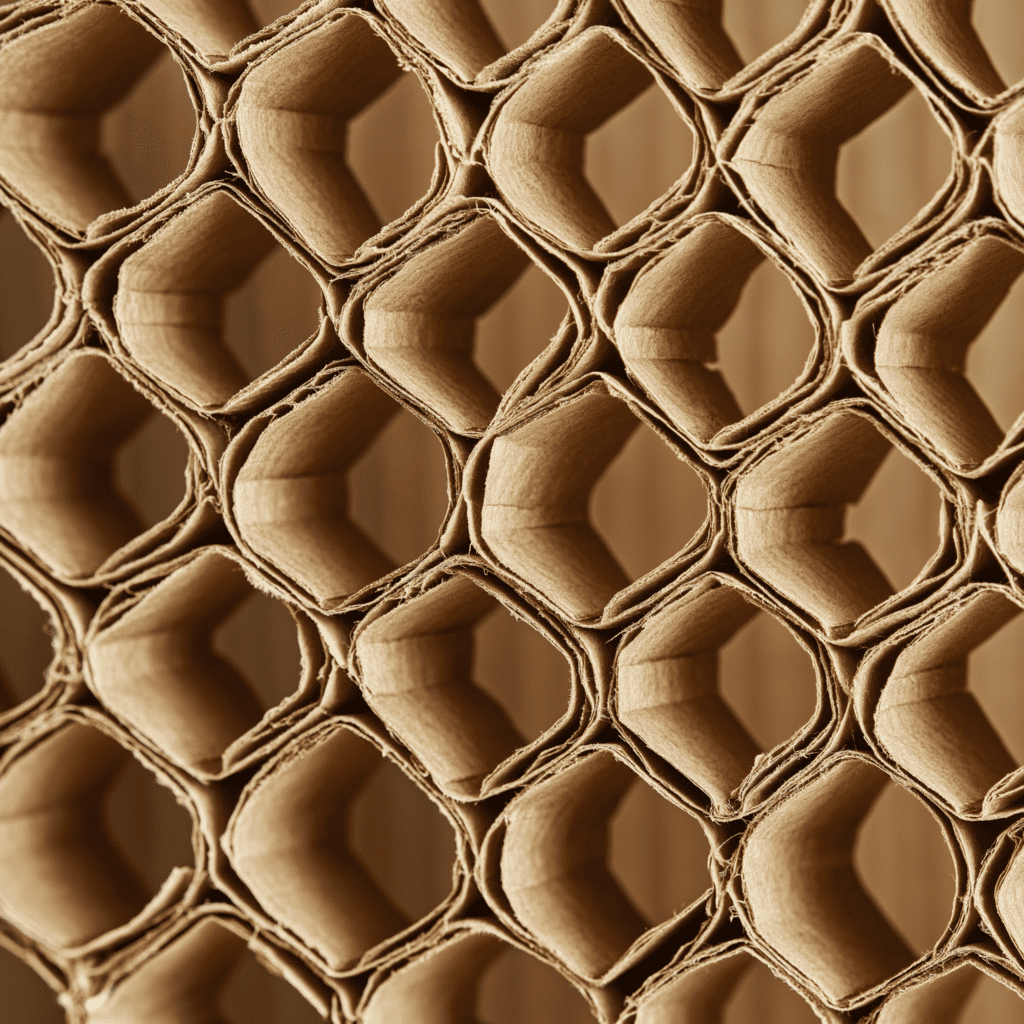

This innovative machine transforms waste cardboard into an effective packaging material, such as chips, strips, or elastic netting, offering a perfect alternative to traditional packaging materials like bubble wrap.

Now, waste cardboard can be repurposed to reduce disposal costs and free up valuable warehouse space previously occupied by bulky packaging.

Using the Eco-Shredder 500, simply insert your waste cardboard, and output read-to-use void fill material, instantly reducing your carbon footprint and contributing to a greener planet.

Here is the complete video for better understanding:

- Motor: Available in single-phase or Three-Phase motor 5HP

- Production: Handles approx. 10 m³/h production

- Warranty: 12-month coverage

- Dimensions: 125x116x100cm

- Weight: 300Kg

- Origin: 100% made in Italy

- Comply with all national and international safety standards.

- Our machines are built to last, backed by top-notch after-sales service.

- Brand new machine with full maintenance and repair services.

- A manual instruction can be provided on delivery.

- For professional training, you may be required to deposit the additional cost of €300.

- For Irish audiences, shipping costs are included in the purchase price.

- We cater to both B2B and B2C customers, with direct sales and financing options available on the website.

- Please contact us for our finance package options.

- Larger motor for superior durability.

- This machine has a connection for a dust extractor system.

- A basic and practical control panel.

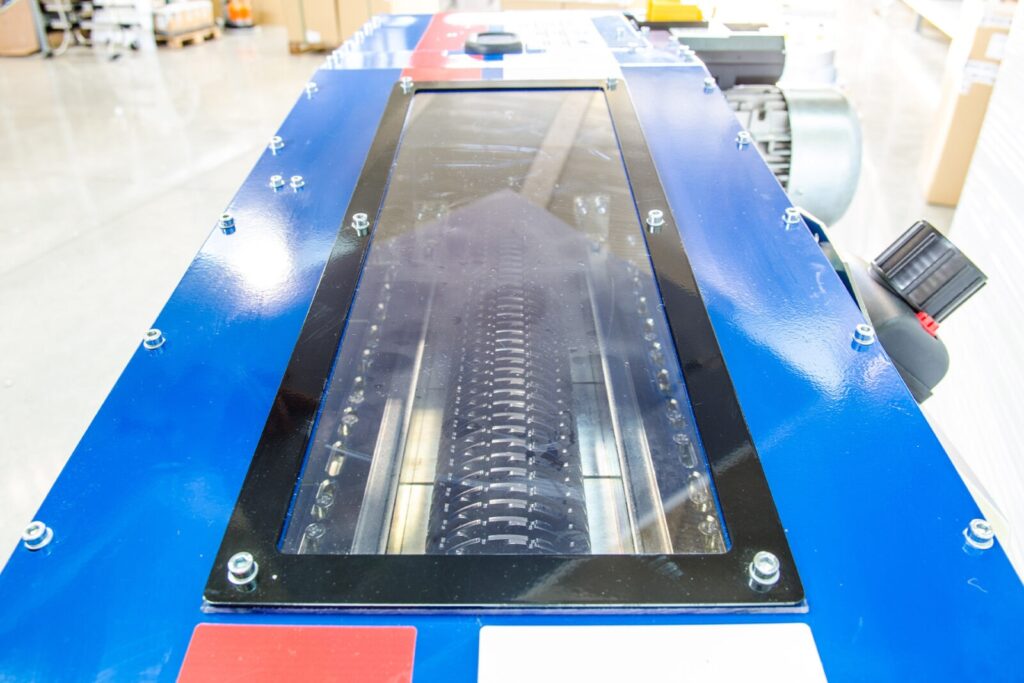

- Robust design with a sheet steel enclosure.

- Reinforcement blades that can withstand even tiny metal pieces passing through.

- Every size of cardboard can be used because of the cutting mouth’s lateral openness.

- Special steel blades that are meant to last for a long time.

- Single-piece load-bearing construction.

- High-speed cutting.

- Hepa vacuum cleaner provision for collecting dust.

- Blade inspection porthole.

- A safety door to keep the blades clean.

- Powder coating resistant against scratches.

- High radial load bearings.

- With an on/off switch, it’s easy to use.

What Are The Benefits?

Save Money, Save Planet

Easy To Use

Efficient & Reliable

Eco Friendly

Minimise Waste

Reduce Carbon Footprint

Let’s Have a Look at Technical Data

Model | Cutting Mouth Width | Cutting Mouth Height | Cutting Capacity | Work Capacity | Motor | Voltage (V/Hz) | Amp | Noise db/(A) | Dimensions (without leg kit)HxWxD | Dimensions (with leg kit)HxWxD | Weight |

500 Network | 500mm | 20mm | 10M^3/h | 8 Hours non- stop | 3HP 1Phase | 220-240V 50-60Hz | 16 | 55 | 111x76x130cm | 127x76x130cm | 250kg |

500 Network | 500mm | 20mm | 10M^3/h | 24 Hours non-stop | 5HP 3Phase | 380-400V 50-60Hz | 16 | 55 | 111x76x130cm | 127x76x130cm | 250kg |

500 Strips | 500mm | 20mm | 10M^3/h | 8 Hours non- stop | 3HP 1Phase | 220-240V 50-60Hz | 16 | 55 | 111x76x130cm | 127x76x130cm | 250kg |

500 Strips | 500mm | 20mm | 10M^3/h | 24 Hours non-stop | 5HP 3Phase | 380-400V 50-60Hz | 16 | 55 | 111x76x130cm | 127x76x130cm | 250kg |

500 Chips | 500mm | 20mm | 10M^3/h | 24 Hours non-stop | 5HP 3Phase | 380-400V 50-60Hz | 16 | 55 | 111x76x130cm | 127x76x130cm | 250kg |

Pivoting wheel kit with parking brake: art. KITRUOTEEDW / Kit 4.0 Ready is Optional on request.

Ecooffset’s 7 E Framework For Environmental Sustainability

Our commitments align with our mission to promote sustainability in the packaging process and contribute to a greener planet in Ireland. We stand out with this framework that encompasses key elements such as assessment, planning, reduction, collaboration, education, improvement, and leadership.

Evaluate

We perform in-depth analyses of the influence on the environment to pinpoint problem areas and determine the highest priority actions.